About Us

Home / About us

Welcome to Radhakrishna Exports

With pleasure, we introduce ourselves as Lucknow / Avadh based manufacturer & exporter dealing with Chikankari Embroidered Readymade Garments, since 1996. We have qualified well trained dedicated work forces of Designers, Artisans and Craftsmen working in and out of our factory. We have Qualified, well trained innovative designers, merchandisers, pattern masters, supervisors, executives, quality analyzers within our factory. We are fully equipped with modernized machineries, equipments with up-to-date technology.

We have different specialized experts to take care of our products, starting from material inspection, colour combination experts, Sample developers, designing and Chikankari quality audit experts, finishing and packing audit and inspections experts in our work place to maintain our quality of product.

We have been regularly exporting our products to different overseas destinations such as various European countries, Japan, Korea, and United States of America, for the last 20 to 22 years. We have worked with various domestic buyers such as BIBA, Pantaloon, Globus etc and we are also working with Reliance, FABINDIA, aditya Birla Group.

We are continuously looking for organizations, who appreciate the value of this luxurious crafts of NaWabs and eager to enhance the look of their present collection.

Our products have been displayed in various National and International exhibitions, such as Heimtextil, Ambiante-Germany, Maison de Object – France, New York Home Textiles Show, Magic – US and India international Garments Fair etc.

Owner's Brief Background

Mr. Rajeev Sharma – owner of Radhakrishna Overseas Corporation holds a Master’s Degree in Business Administration from University of Allahabad. Earlier he worked with the public sector for few years in computer industry and later stepped ahead to start his very own garment production and exports business in Lucknow.

Mr. Sharma is an acclaimed entrepreneur with decades of experience in garment export. He has been honored with many state and national awards for his works and business practices. He also runs initiatives to preserve heritage arts and handicrafts of Awadh besides providing employment to skilled craftsmen and artisans who are a part of in organizations sublime work force.

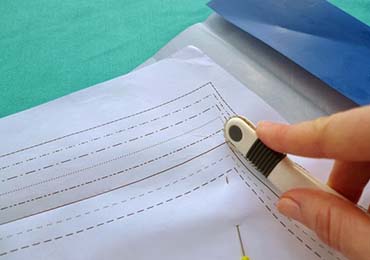

Our Work Process

How our products are made to life before hitting the wardrobes.

-

PRE-CHECKS OF GARMENT PRODUCTION

The raw material gets checked before getting through the production line, such that it meets our high standards of quality garment production. Sample development and approval is also done in this stage.